HOW DOES AIR PRESSURE IN CLEANROOMS

WORK?

The passage of air from high to low pressure is a well-known

natural phenomenon. Every day, we are surrounded by examples of this. Wind and

weather are created as the earth’s surface heats unevenly, resulting in pockets

of high and low-pressure air. If you’ve ever seen a door suddenly close as air

is sucked out of a room where there was no breeze, you’ve seen high-pressure

air traversing to a low-pressure place to achieve stasis. The air escaping from

from a high-pressure environment to the relatively low-pressure environment

around it.

When air is travelling in one direction, it does not move in the

opposite direction in any of these conditions. As long as the air inside the

balloon is more pressured, there is no air coming into the balloon when air is

moving out of it. This technique can be used in cleanrooms to block the flow of

air into or out of the room, minimizing particle transmission and ensuring a

cleaner environment.

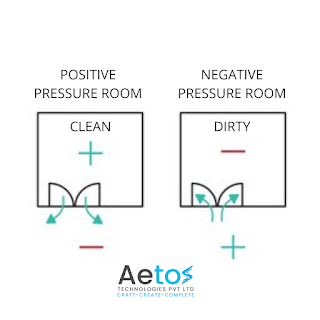

To put it another way, higher pressure air within a cleanroom

(as compared to outside air) prevents pollutants from entering the cleanroom

because air naturally wants to flow out. Lower pressure air in a clean room, on

the other hand, can trap pollutants and prevent them from exiting because the

natural flow of air wants to move in.

Pressure in cleanrooms, either higher (positive pressure) or

lower (negative pressure), can be quite useful in a variety of cleanroom

applications – but how do you include it into the cleanroom design?

v USING PRESSURE IN CLEANROOM DESIGN

Controlling how much air is pumped into the cleanroom and how

much is evacuated creates positive and negative pressure in cleanrooms.

Clean, filtered air is continually pushed into a positive

pressure cleanroom via the HEPA filtration and clean room HVAC system. If a door

or window in the cleanroom were to be opened, air would rush out into the

outside world or recirculate through the AHUs.

This positive pressure ensures that the products and operations

within the cleanroom are safeguarded in the case of a breach or leak. The air

is driven out of the cleanroom due to the positive pressure, preventing

contaminated or unfiltered air from entering.

External exhausts draw air from the cleanroom at a higher rate

than air is added over time to generate negative air pressure. As a result of

the negative pressure, air will desire to flow into the cleanroom to fill the

low-pressure space, thereby preventing pollutants from escaping the cleanroom

against the natural flow.

Cleanrooms require neighboring spaces to be kept at a lower or

higher pressure than the cleanroom to maintain positive or negative pressure.

If you incorporate a pressurization system into your cleanroom

design, a pressure monitoring system is essential for maintaining balance and

consistency. The pressure will be checked and maintained by the monitoring

system, which can be adjusted manually or automatically.

v POSITIVE PRESSURE CLEANROOM APPLICATIONS

Positive pressure cleanrooms, also known as high-pressure

cleanrooms, are highly beneficial in applications where even the tiniest

particle interference could damage cleanroom procedures. Positive pressure

cleanrooms are beneficial to businesses that are particularly resistant to

contaminating particles, such as semiconductor cleanrooms, microprocessor

cleanrooms, and aerospace and defense cleanrooms. Positive pressure is used in

many medical cleanrooms to protect delicate patients and maintain a controlled

environment.

Using slightly positive pressure in cleanrooms can assist

achieve cleanroom classifications and maintaining a cleaner environment even

when the stakes aren’t nearly as high.

v NEGATIVE PRESSURE CLEANROOM APPLICATIONS

Low-pressure cleanrooms, also known as negative-pressure

cleanrooms, are appropriate for applications that require the isolation of substances,

particles, or fumes inside the cleanroom environment to safeguard the

environment outside the cleanroom. They’re commonly utilized in medical

cleanrooms, as well as for medical research, testing, and the development of

sensitive-substance treatments.

Negative pressure is also used in cleanrooms for pharmaceutical

purposes as part of a segmented arrangement. Lower pressure is maintained in

one chamber, while a slightly higher pressure is maintained in the ante-room

directly outside. This permits staff to enter the negative pressure area with

as little disruption as possible.

In cleanroom environments, high and low pressure, or positive

and negative pressure, can both be employed as instruments to defend against

entering contaminants (in positive pressure cleanrooms) or contaminant leakage

(in negative pressure cleanrooms) (in negative pressure cleanrooms). We can

create cleaner, safer cleanrooms by utilizing the natural movement of air

caused by pressure.

Reach out to Aetos

Technologies Pvt. Ltd. for any cleanroom-related solution, Lets connect

at

sa***@ae*******.in

or visit www.aetostech.in